挽手 Top handle

Handle base is made from the multiple cellulose/microfibre/latex reinforcements and padded

with the Barenia leather at both ends for more resistance against the pull.

Top leather was then molded over the shape of the handle and trimmed. Edges got painted

in multiple layers and handle is stitched together.

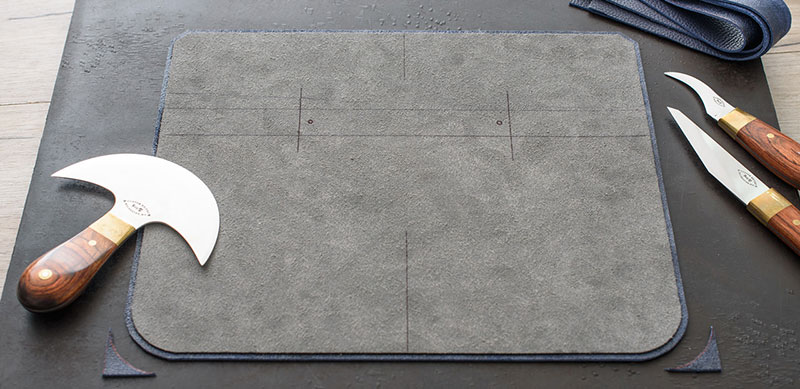

包盖 Flap

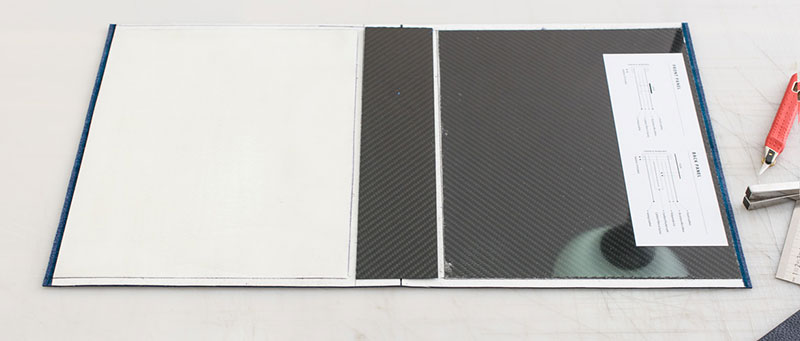

Flap is cut and glued to the first layer of internal reinforcement. Tricky part was to cut exactly 3mm from

the edge of the reinforcement, so the flap joined with the lining won’t have too thick edge.

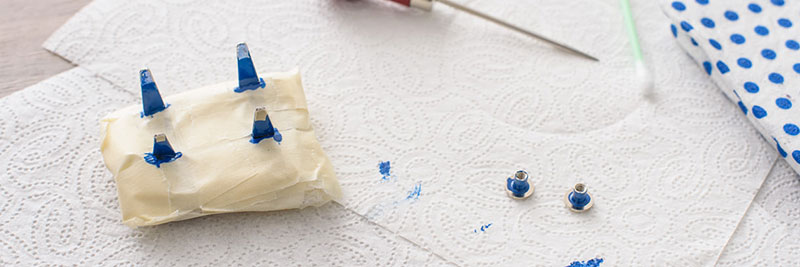

Handle holder holes are prepared with an oval punch, together with centered holes for support bar screws.

I hate painting inside edges of the holes, it is a slow and tedious process, since paint can spill quite easily

to the leather and damage it permanently.

Support bar will keep the rectangular shape while carrying the bag with the handle. It’s hold with two

chicago screws and it’s covered in a textile tape to soften the edges.

Stitching handle holders to the flap. Because they will hold the bag weight with a relatively small

surface, they are reinforced with Kevlar sandwiched in microfibers.

Handle is attached in the holders. Lining will be then glued under the curve

similar to the angle of the closed flap.

Platform for the flap part of the closure lock is cut. However, closure has metal attaching prongs that can create bulge on the front side of the flap. To hide them, another layer of padding is glued to even the surface on the back of the platform.

Closure platform is stitched to the flap lining only, so the stitching won’t be visible

on the front view of the bag.

Flap is edge painted and stitched. Stitching sits in the channel created by the 3mm shorter

reinforcement underneath the leather.

Finished handle is then joined with the main body composite. It’s stitched before the lining, so the

stitch line won’t show inside of the bag.

最后组装 Final assembly

After all the parts are joined together, lining is stitched to the front leather on both ends with a french

binding technique, finished at the end of the reinforcing plates. Edges of the body are then painted. After drying, prepared gussets are stitched to the side of the body.

Finished bag can stand on its own and keeps stability. Hooray.

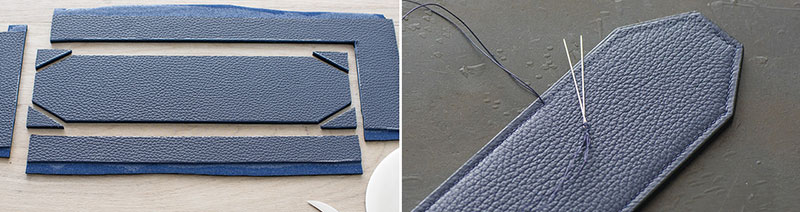

肩带 Shoulder strap

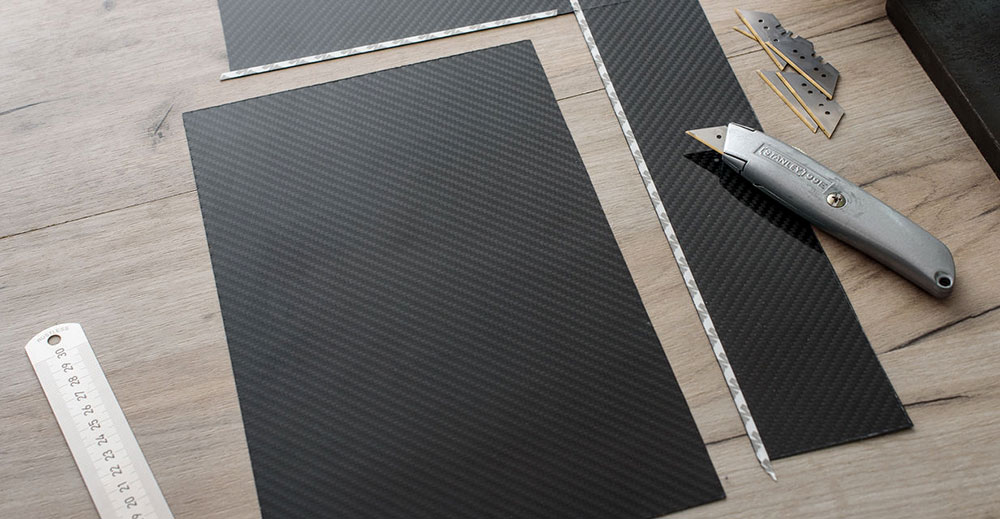

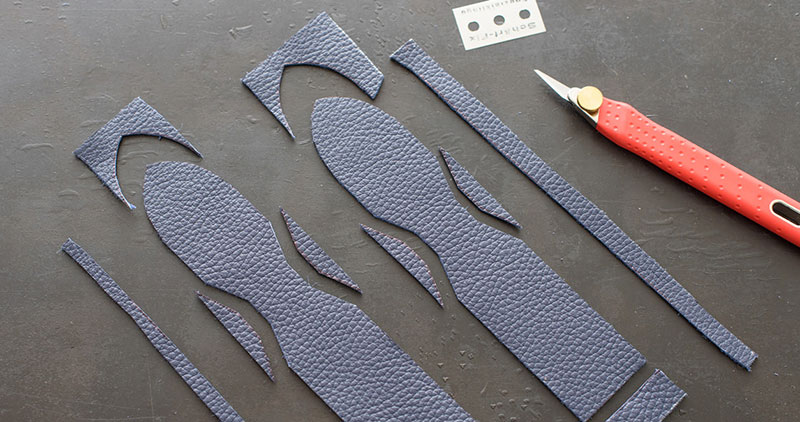

Cutting the shoulder straps from the two layers of leather with the 500 denier Cordura reinforcement

in the middle. Reinforcement will prevent natural elasticity of the leather to stretch the strap out of shape.

Padded middle part of the shoulder strap has a technical suede made for performance shoes – it’s soft, thick and retains basic firmness during pressure. Together with Cordura it’s sandwiched between two layers of leather. Stitching through multiple thick layers can be challenge.

Loops are made to keep the straps from separating from each other. In the middle ends are joined with

a double cross stitch.

After painting the edges and preparing stitching holes, straps are hand stitched with the installed

palladium hardware – hooks and sliding buckles.

The shoulder strap is finished. On both ends are sliding buckles, which allow to fine tune the length

(single shoulder or cross body).

As a last step, I filled the bag with air pillows and left overnight to set the leather to the final shape.

I usually do projects with friends or people recommended to me by friends. This was actually my first project for someone I don't know and I was bit skeptical about whole experience.

However, it turned to be really productive collaboration. Kevin had clear design vision but at the same time, he listened to arguments, so project was very enjoyable.

皮小匠-手工皮具教程,免费分享图纸

关注我们,及时查看教程